The Problem

You mount a scope on your brand new rifle and can’t get it zeroed because it’s run out of adjustment.

The Background

About once a month I’ll run into a question posted by a user on one of the Internet’s hunting and shooting forums with just such a problem. Problems with rifles can very often be traced back to malfunctioning scopes or faulty mounts but, in this case, the usual suspects are innocent.

The Expert Deferral

I’ve struggled to get some test guns shooting on paper, but my exposure has been minimal. I also lack the test equipment to determine the culprit when a situation like this strikes. My friend D’Arcy Echols, one of the nation’s preeminent rifle builders, has seen this situation countless times. He weighed-in on this topic when I was in his shop last fall and again recently on a popular outdoor message board.

“It is not to uncommon to find the receiver threads machined out of line with the centerline of the bore and pointing off into deep space. On the few left handed Model 70 actions I have assembled this situation should be considered a given. If the amount of run-out is minimal and you install a scope with maximum amount of windage and elevation correction available or install iron sights only on the barrel you will likely never perceive this as a problem.”

“If the run-out is significant you will run out of windage correction unless you use the older style Redfield or Leupold windage screw bases. If you install a peep on the rear bridge you may find the windage correction to zero the rifle will require the windage slide to hang way over the sight base to left of right of the center line of the base to allow you to zero the rifles point of impact.”

“Scope mounting holes can also be drilled off the centerline of the bore, this is a reasonably common occurrence.”

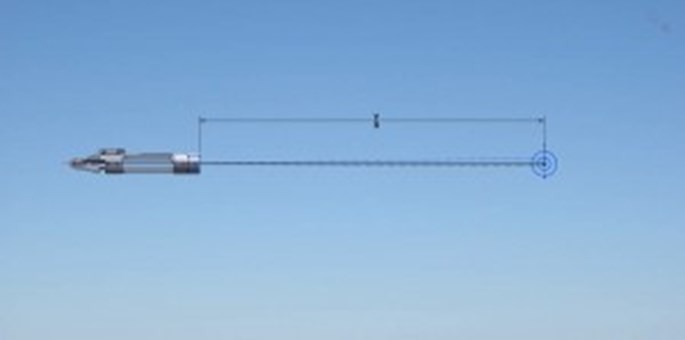

This graphic created by D’Arcy illustrates what an extreme case of run-out (1 degree on .750” of threads) would look like.

One Extreme Example

“I was sent a Rem 700 a few years back that did not shoot with the factory 257 Roberts barrel, was re-barreled at Shilen to 257 Roberts a second time and is still didn't shoot, then sent to a “Neoandro-smith” to change it to 270 Win and, no, it didn't shoot. We noticed that the barrel threads were "way the heck out" as soon as we removed the barrel. Instead of fighting an uphill battle, we sent the action to Mark Penrod as he has all the fixtures and tooling to really go over 700s. He enlarged the threads in the action to remove the run-out and installed a 4th barrel chambered for 257 Roberts. The rifle now shoots very tiny groups, one after another.”

“The stock’s barrel channel was almost razor thin on the right side as the barrel was pointing off on such an angle to the right due to the thread run-out that a severe amount of forend had to be milled away to allow any free float on the effected side. When corrected, the 4th barrel ran visually straight down the centerline of the forend, or what was left of it.”

The Solution

Many custom gunmakers, Echols among them, recut the receiver threads and recut the face of the action so that the bore is square and concentric with the centerline of the receiver.

“Since I have insisted on having the treads re-cut, the scope base holes tapped on center and inline, and the action trued, these ‘problems’ have gone away.”

“This may still not be true but, at one time, the Leupold 1.5-5x20 had about as much elevation and windage correction as any sporting rifle scope for the hunter. If I recall, it was right at 72 total included inches or 36" in either direction from the center of the reticle adjustment plane. In the past, even after truing-up the face of the receiver, the lugs etc. I ran out of windage correction at least twice and elevation once. After the 3rd encounter, I have had the action threads re-machined so they're as close to the centerline of the bore as is possible. I have not yet figure how to re-thread a 98 with the inner collar in a reasonable fashion. It is simple to true up the front face and shoulder of the inner collar but correcting any thread from run-out is pretty damn hard. I find it best in the case of the 98 to select the action as carefully as possible and look for excessive misalignment before you use it.”

Often, these problems arise when the receiver is improperly drilled and tapped for scope mounting. When scope mounting holes are drilled off-center, gunmakers often re-drill them to accept larger 8-40 mounting screws which enlarge the hole’s surface area enough to correct the misalignment. “That usually works” said Echols. “On two occasions, one only a month ago, I used 10x32 screws, which is the max size you can use and still have adequate enough thread engagement in the front receiver ring. If the base holes are still way to hell off you will need to drill the holes in the scope base off center the required amount, this I have also done.”

Scope mounts and the alignment of the mount with the centerline of the action and, of course, the centerline of the bore is equally important. “One of the actions where I encountered this was on one of Tom Burgess's tricked-out Enfields. The action had a set of his detachable mounts installed that utilized a male dovetail on the both the front and rear bridge. Tom had cut the dovetails on an incline that ran uphill towards the muzzle. In the 5" distance the added incline was about +.020, if I recall. That .020 of incline wiped-out all the elevation adjustment and left the point of impact at 100 yards 1" low with no other come-up left in the adjustment. This was corrected by re-machining the angle of incline into an angle of decline towards the muzzle.”

“With the modern 700 and more so with the precision made clones like the Defiance, Stiller, Borden, etc., these are no longer an issue but in 1898 and 1930 it wasn't even a consideration. And that is the reality: it’s not that these actions are junk, poorly made, or useless, but our accuracy demands, sight parameters, extended range usage, etc. today are so much different then they were 100 years ago.”

Just a few of the problems and processes that go into making a true custom rifle, and one of the reasons that good ones don’t come cheap.