The AR platform, once relegated to the sidelines of the hunter’s world, has really come into its own in the last decade. It was a slow integration. Long before electronic frills, changed-up chamberings and free-float handguards, these rifles came to dominate the predator-hunting scene thanks to their rapid muzzle velocities and comfortable capacity, enabling hunters to tackle packs and sounders with ease. Amid all the modern enhancements of the AR-15, this got me thinking—what would be the perfect AR-15 for a predator hunter? Would it have a 20-inch, rifle-length barrel or would it be a carbine? Ultralight components, or would it retain some heft for accuracy? Then it hit me. Predator hunting is all about high accuracy, high speed and high volume, the same hallmarks of modern precision gas-gun competitions. In fact, what better way to keep skills sharp in the offseason than to make a coyote gun that also has the right specs to shoot competitions? This in mind, I reached out to some of my comp-shooting friends, as well as my fellow hunters, and got to work on what I hope is the perfect all-around AR for the predator hunter.

Frame Up

The first time I built an AR, I spent months obsessing over the first component: the lower receiver. I looked at all sorts of different brands, and compared weights and materials to the point of utter paralysis, until a friend gave me a reality check. “What are you so worried about? It’s a bucket to hold your trigger.” While this may be overstating the case a touch—I would still recommend getting a quality, mil-spec lower to ensure your pins fit tight, buffer tube threads and magazines lock in securely—the spirit of the answer is completely correct. Of all the components on an AR-15 that affect accuracy, the lower receiver might just be the least important. Buy quality, but don’t go nuts overthinking it. Not so, however, with the upper.

When looking at upper receivers this time around, I had a similar reality check from another friend, who happens to be a dedicated competitive shooter of no small experience. “Make sure it’s a thermal fit.” … “What on earth is a ‘thermal fit?’” I wondered. For me, precision guns have always been my turn-bolts, while my ARs have, for lack of a better term, been crude bullet launchers.

It turns out, along with the barrel itself, a “thermal fit” is probably the single largest component affecting accuracy potential on the rifle. A thermal fit upper means that the upper receiver is equipped with a bore size ~.003-inches under a standard Mil-Spec bore (1.000 -0.0/+0.002 inches). This means that the barrel extension, rather than just sliding in snugly, will actually not fit into the upper when both are at the same temperature. Instead, you have to take a heat gun, heat the upper and slide the barrel in when the upper is still piping hot. I also found throwing the barrel into the freezer while heating the upper made the process even easier. This fitment ensures a much more tight and reliable connection between upper and barrel, keeping the barrel perfectly in line with the upper and, in turn, keeping the bolt’s pressure equal all around the base of the cartridge, aligning the firing pin in the exact same place every time. In short, a thermal fit upper takes virtually all of the wobble out of the barrel and accuracy equation. Thus, component one to top my host Ruger lower became a Centurion Arms CM4 5.56 Thermal Fit Forged Upper Receiver.

Through the Barrel

Before moving onto the details of the barrel, let’s take one step back and explain my choice of chambering. As mentioned, this needs to be a build that prioritizes accuracy, but also volume. Depending on their preferred prey, predator hunters can shoot quite a lot in one outing, and there is simply nothing as cheap to shoot as 5.56 NATO/.223 Remington. That in mind, I was fairly certain I wanted to stick with a .223 Wylde chambering that could handle both cartridges with ease. The question was, how could I pull the accuracy I was looking for out of this stalwart yet rather light old military cartridge? Luckily for me, the gunsmiths over at Sons of Liberty Gunworks (SOLGW) had been asking themselves the same question for quite some time, and have come up with a solution.

SOLGW has developed what it calls its Precision SPR Grade Barrel, chambered in .223 Wylde, crafted from 416R Stainless Steel and sporting a 1:7-inch twist in its polygonal rifling. With an SPR contour, it is far from the lightest barrel on the market, but it does advertise half-MOA groups with multiple different types of (heavier grain) ammo, all while measuring just 16-inches long. A little heavy, but accurate and highly maneuverable? That’s a predator hunter’s dream right there.

There’s another reason this particular barrel drew my attention, and it has to do with the competition side of the build. One of the most realistically useful competitions for gas-gun hunters in the country right now is the Quantified Performance (QP) series. Gas guns only, QP’s championship series is called “Shoot Fast Shoot Far,” and they make their shooters do it from a variety of different positions throughout multiple timed stages during every match. There are three divisions one can shoot in: General Purpose, Practical Precision and Open. This barrel, along with the optic I had in mind, would make the gun a real contender for General Purpose—the two main requirements of which are barrels under 16.5 inches and optics with a maximum power of 8.5x (or a lower power of under 1.2x). We will come to the optic later.

Atop the barrel, I ran a mid-length AeroPrecision gas tube paired with a Superlative Arms adjustable gas block, to make it easy to tune my eventual load/buffer/suppressor combination. It also has a patented bleed-off setting for optimal cycling I was curious to see in action.

Around all this I installed a Cross Machine Tool UHPR 13.7” Mod 2 HDx free float handguard. With a Pic rail on top and M-Lok on the bottoms and sides, it’s a great, sturdy handguard that does exactly what it needs to—nothing less, nothing more.

Bolt and Trigger

You can’t have an accurate lockup without a solid bolt carrier group (BCG), and the Battle Arms Development AR15 BCG is about as solid a choice as you can find. Machined from Billet 8620 case hardened steel, with a 17-4 H-900 steel center-less firing pin, this is a BCG that will stand up to abuse and keep running. Even its gas key is machined from 4140 steel billet, staked and attached with Grade 8 screws, with a cam pin of the same material. A black nitride finish along the body is corrosion and wear resistant with little lubrication (though let’s be honest, you should still run it well lubed when you can). Finally, the bolt itself is 9130 steel, shot peened, CNC ground after heat treating, and sports its own black nitride finish. Its extractor is 4140 billet, with a manganese phosphate coating for more positive grip. Every single component of this carrier group, as well as what it is made of, has been thought out and selected to best accomplish its task. More thought has been put into this one component than some entire firearms.

The trigger might be the most shooter-specific selection on the entire gun. In terms of the firing process, all the trigger mechanism is responsible for is hitting the firing pin. It is, quite literally, a blunt instrument that needs to be reliable, but has little effect on potential accuracy. Put the shooter into the equation, however, and the trigger quickly becomes one of the most important components on the entire firearm. Why? Because it doesn’t matter if you have a gun capable of .25 MOA accuracy; with a 10-pound, rough, inconsistent trigger, the chances of most shooters being able to squeeze that sort of accuracy out of the rifle are slim to none.

For a double-duty, competition and hunting trigger, I wanted a trigger light enough to be easy to shoot, but heavy enough to not be a concern when bumping through the woods at night. I also wanted something with two smooth stages that would be easy to stage for precision shots. Luckily, Timney Triggers had just the ticket. The company’s AR Targa Short Two Stage Trigger has a two pound first stage and two pound second, for a total of four pounds overall. Smooth, predictable and easy to manipulate thanks to its equal stages, I opted for the straight trigger profile due to its more easily repeatable indexing.

A true drop-in design, the trigger is a breeze to install. Simply drop it in, slide it under the safety selector and drive in the pins. Don’t forget to tighten down the two small tensioning screws though—the trigger will not reset properly without them holding it firmly in place (ask me how I know …).

Grip and Stock

When you need to take a firm, positive hold of something, be it a magazine or a rifle, it’s generally wise to look at Magpul. This case is no different. The company’s MOE K2 Grip and PRS Lite stock were perfect for my use case, as they combine secure purchase with interesting adaptabilities.

For starters, the MOE K2 provides the ergonomic, vertical grip angle currently favored for precision shooting, thanks not only to the angle it allows your finger to find on the trigger, but also the additional comfort it provides when actuating the safety selector on the shooting-hand side of the rifle. Shooting with your thumb in this position tends to be more accurate, as it eliminates any unwanted inputs on the rear of the grip caused by wrapping your thumb around back. Even cooler, the MOE K2 has a removable core, in which you can store random odds and ends, a bottle of lube, or even a spare bolt. Whether you’re thinking hard competition use, or long nights in the field away from supplies, that’s a pretty cool bonus.

The PRS Lite stock, meanwhile, is a great balance of weight, ergonomics and adaptability. The stock weighs just 18.5 ounces (not counting the buffer tube), features a length of pull (LOP) adjustable in .14-inch increments, and an adjustable cheek piece to customize the height of the comb. The result is the perfect stock for a hunter. Light enough to take afield, it is adjustable enough to find the perfect settings, while lacking the quick-adjust features that can drive up weight on more competition-focused models. LOP ranges from 13.9 to 15.3 inches, while height extends from 5.2 to an even 6 inches, for almost a full inch of cheek comb adjustment. That may not sound like much, but it is more than enough when it comes to cheek weld.

On a related note, to achieve the aforementioned grip position while still being able to actuate the safety, I installed an Armaspec ST45, 45 degree short throw ambidextrous safety selector. Short and smooth, it makes it so I barely have to move my thumb to toggle the lever.

![]()

See Far Shoot Far

In many ways, the optic you choose is as important as the entire rifle. It doesn’t matter how accurate your rifle is if you can’t see exactly where you want to hit on your target, and it matters even less if, when out past your point blank zero, your yardage adjustments have your lead flying in a shotgun pattern. For this specific build, I also needed the scope to meet LPVO requirements, both to keep it within spec for competition and to make it more realistic for close-range work on packs and sounders. Luckily, I knew just where to turn.

![]()

The Trijicon Credo HX 1-10x28mm is the best LPVO I’ve ever used. I am always loathe to use such seemingly exaggeratory language, but in this case it’s simply true. With 1-10x magnification, this Credo HX has a higher top and lower bottom magnification than my deer-rifle scope, has internals designed for crystal clarity from dawn to dusk, and even has roughly 100 MOA of hold and hash marks visible in every direction of the reticle (except down, of course). If that wasn’t enough, its turrets allow for 136 MOA of ballistic adjustment in every direction, and its tracking is dead on. I would know, I did a full Hardware review on the scope, where I tested it for accuracy, consistency of adjustment and durability. If you’re interested in a detailed breakdown of the scope, check out that article here. For our purposes right now, suffice it to say that this 34mm tube, illuminated reticle riflescope is hands down the right tool for this job.

Muzzle Device/Suppressor

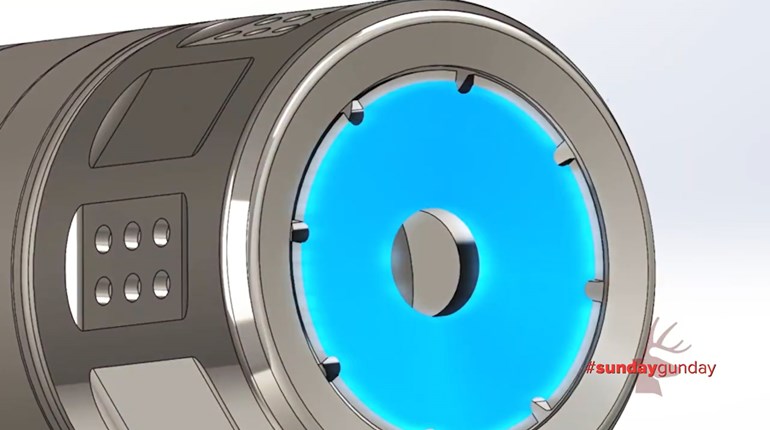

I had a few options for muzzle device and silencer, but decided early on I wanted to go with a Dead Air. Some brands have a reputation for rugged durability, while others rely on constant innovation and slick designs. Dead Air does both. Initially, I was sold on the Sierra 5. Dead Air’s 5.56-caliber workhorse, the Sierra 5 is a true, no-nonsense, function-over-form receiver that is short and maneuverable to boot. Crafted from stainless steel with welded Cobalt 6 baffles, it’s even full-auto rated for heavy firing schedules and extends just 4.87 inches in length, while tipping the scales at 10.7 ounces. Indeed, it’s a pretty dang perfect can for the field. Then the company announced the release of the Sandman X.

Created from Haynes 282, a gamma-prime strengthened superalloy, the Sandman X is actually a .30-caliber suppressor, but designed with the AR platform in mind. It has a 4200 ft.-lb. energy rating—in addition to full-auto capability—and weighs in at 14.5 ounces sans adapter. While longer than the Sierra 5 at 6.4 inches, the magic of the Sandman X is inside. The suppressor uses two patent-pending Triskellion baffles and three cone baffles, all surrounded by a Triskellion Gas Management System. This hard-use system yields great acoustic performance (just 138 dB at the ear, on a 16-inch barreled AR), but even more importantly, provides excellent flash reduction. I shoot my coyote guns under NODs fairly regularly, so flash mitigation is almost a more important trait for one of my suppressors than noise reduction. Still cooler, the Sandman X uses Dead Air’s R-Series front caps (as does the Sierra). I currently have the flash hider cap installed for the previously mentioned reason, but should I want to focus more on recoil reduction I could screw it off and install the company’s E-Brake directly onto the end of the suppressor. If that’s not the best of both worlds, I don’t know what is. Lastly, the Triskellion system minimizes backpressure, which eases wear and tear on components in this gas-operated platform, while simultaneously reducing the amount of lead particles I’ll eat behind the gun. Win, win, win, win.

Both these suppressors set up to mount directly onto Dead Air’s 3-prong Xeno Flash Hider, so I can swap either on or off with ease. While I’ve a feeling the Sandman X will stay mounted on this particular carbine nine times out of 10, it’s nice to have the flexibility to throw on the Sierra 5 if I’ll be humping the gun long distances or through denser cover.

Hornady Match BTHP on right, Federal Gold Medal Center Strike on left

Hornady Match BTHP on right, Federal Gold Medal Center Strike on left

Ballistic Results

Now comes the important part. All the components sound fancy and great, but how does this Frankenstein’s monster actually shoot? I won’t leave you in suspense—the gun is lights-out accurate and maneuverable to boot. Sans accessories (scope, bipod and can), it tips the scales at 7.6 pounds. This climbs to 11 pounds when you add those items. While that’s certainly on the heavier side for an AR it’s by no means a bench queen, and can still be easily shot offhand. Accuracy though, is where the numbers really shine. For this, I took a selection of heavy-for-caliber match-grade ammo and selected the three best performers without any bias toward exact grain weight or brand. Each was shot for three, three shot, magazine-fed groups. The results speak for themselves.

Here's the crazy part. Good as these results are, there is likely even more potential accuracy in the gun. I say this primarily because the Credo HX 1-10x28mm lacks a super-fine aiming point. When on or near full magnification, the center dot is a little chunky, and blocks out more target than is ideal for bleeding-edge precision. Unfortunately, there was no way around this. As I learned from John Fink, the Magnified Optics production manager over at Trijicon, they tried to go with a finer crosshair, but it became basically invisible when zoomed out. This was as thin as they could go while still maintaining realistic utility at one power. A worthy tradeoff in service to a great all-around scope, but not ideal for this particular scenario—at least not for me, I'm sure there are better shooters who could have wrung a little more accuracy out of it.

Spartan Precision's Vidarr bipod utilizes the company's Disc-Lok attachment system to clip on and off with ease. Leg-height adjustment is spring loaded, the bipod both pans and tilts, and despite the easy Disc-Lok attachment, it can still fold up when you want to keep it on the rifle for transport.

That aside, even the largest groups still didn’t top an inch. This is a gun that will hit a 7-inch gong at 700 yards 10 times out of 10 if you do your job correctly, and will likely put its group within the middle 5 inches. (NOTE: I’d say a 10-inch at 1000 to make the math easier, but there is a good chance the bullet has gone transonic by then, which destabilizes it a touch. That’s not to say it can’t be repeat-ably done—I’ve seen it in competition from carbine-length .223-chambered ARs—but potential accuracy does become less predictable).

Short of going with a longer barrel which adversely affects maneuverability in the field, or a more powerful scope which adversely affects close-in performance, I’d say this is about as accurate as you can make a standard AR without some really fancy gunsmithing and custom handloads. Check back here in the future for a report on how the gun performs in competition and in the field. I’ll post a link to that article here when it’s live.